Abstract

In this paper, the effect of washing parameters on the quantity of dye discharge from fabric dyed in highly saturated color (FSC) was discussed. Firstly, the FSC was prepared with reactive red 195 to represent the dark clothes. Secondly, the effect of the washing parameters, including washing time, washing temperature, washing water volume, the weight of FSC, and the dosage of detergent, on dye discharge was analyzed through the single factor test. Thirdly, the mathematical relationship between the quantity of dye discharge (DDQ) and the four washing parameters was discussed through the center combination experiment and response surface method. And a quadratic model was built to predict the quantity of dye discharge when the FSC were washed with different washing parameters. The experimental results indicated that the quantity of dye discharge was affected by the four selected washing parameters and the optimal washing parameters to reduce the quantity of dye discharge can be deduced from the quadratic model. The optimized parameters effectively reduced 0.99 mg dye discharge per liter, and the DDQ reduction rate was up to 53.5%.

Introduction

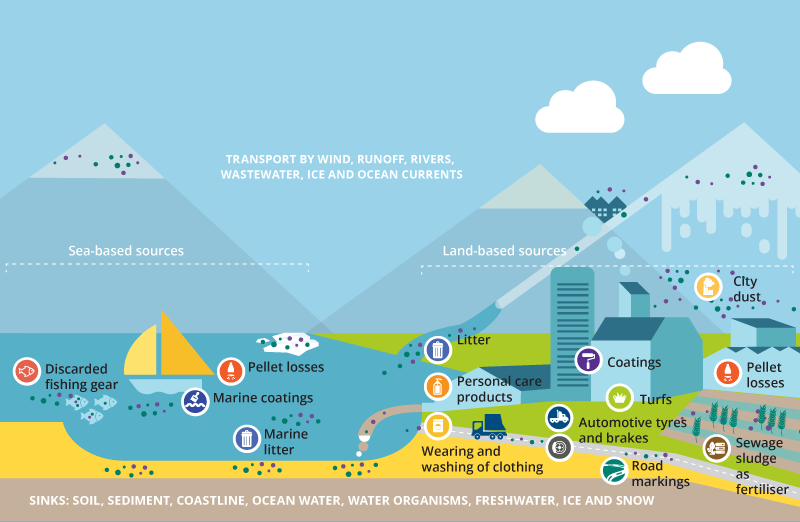

Cotton fabrics are made of natural cellulose fibers, which have the advantages of moisture absorption, breathability, comfort, and mild handle, and are favored by consumers. With the improvement of people’s living standards, the color requirements of cotton fabrics are also increasing. Reactive dyes have the advantages of various colors and low cost and become the first choice for cotton fabric dyeing (Lewis, 2014). However, due to their structural characteristics, reactive dyes are easily hydrolyzed and shed by temperature, sunlight, washing, and other effects (Lu et al., 2014). Due to the defects of deep chroma, poor biodegradability, and large diffusibility, the shedding reactive dyes cause large fluctuation of water quality and high chemical oxygen demand (COD), which seriously affects the ecological environment and human health (Bezerra et al., 2021).

In daily washing, people often mix a large weight of Fabric dyed in highly saturated color (FSC) and light-colored clothes for the convenience of washing (Guo et al., 2020). Due to the defects of the dye itself and the improper post-treatment process of dyeing and finishing, the floating color on the surface of the fabric accumulates, which leads to low colorfastness to washing. Under the mixed action of washing parameters, the dye shedding is aggravated (Kongliang et al., 2006; Wei et al., 2016). On the one hand, the dye content in the washing wastewater is high, resulting in wastewater pollution, on the other hand, it causes cross-color of light-colored fabrics. Previous studies have shown that the dye discharge of fabric dyed in highly saturated color (FSC) is related to pH, the type of dyes, fiber type, temperature, water hardness, mechanical strength, and so on (Gorenšek 1999; Hu & Fan, 2013). Fan et al. studied and analyzed the reasons for poor color fastness to wet rubbing of reactive dyes, which mainly described that alkaline dyeing of reactive dyes led to the formation of hydrolyzed dyes attached to fibers, which reduced the color fastness to wet rubbing (Fan et al., 2006). Bilisik et al. studied and analyzed that the dye uptake of FSC is high, the dye dispersion density is high, and there are still many floating color residues after a series of post-dyeing treatments. In addition, due to the hydrolysis of the dye itself, the covalent bond between the dye and the fiber is lost, so the dye will fall off into the washing solution when washing the FSC (Bilisik & Yolacan, 2011).

Therefore, how to find a set of washing parameters that can effectively reduce the quantity of dye discharges (DDQ) in the washing wastewater and the prediction model of the quantity of dye discharges (DDQ) become the focus of this study. The traditional orthogonal experimental design method can find the best combination of factor levels affecting the test results, but its disadvantage is that it can not give a comprehensive expression of the relationship between factors and response values in a certain region, that is, the regression equation, so it can not optimize the best combination of factors (Tang & Cai, 2006). Therefore, it is particularly important to find a test method that can effectively reduce the number of experiments, shorten the test period, obtain the regression equation of factor-response value, and obtain the influence of interaction between various factors on the response value (Kalpana & King, 2014). In this study, the central composite experimental design method was selected to design 30 experimental points with alternative combinations of various factors. The pivot point selectivity of central composite experimental design, the spatial and rotatable nature of experimental data, and the combination of response surface analysis could greatly improve the accuracy of the prediction model (Baaka et al., 2015).

Therefore, to deeply simulate and study the influence of the combination of washing parameters on the dye discharge of FSC in household washing, five groups of single-factor experiments were carried out on washing time (A), washing temperature (B), washing water volume (C), the weight of FSC and the dosage of detergent (F). The parameters that significantly affected the dye discharge were determined, as well as the distribution of significant intervals. Then, the effects of the interactions among the four washing parameters on the dye stripping quantity of FSC were analyzed by central composite design, and a Quadratic model was established to fit the experimental data to obtain a quadratic regression equation, to predict the effects of washing parameters on the dye stripping weight of FSC. Through the fitting optimization and verification test, the parameter collocation of effectively reducing dye shedding and the most dye shedding was obtained, which provided a theoretical reference for the prevention and control of dye shedding pollution in household clothes washing.

Methods

Materials

The bleached cotton fabric was used to prepare the FSC, the linear density of the warp and weft yarn of which are both (27.8 ± 2.5) tex, with both (235 ± 5) picks/10 cm in the warp and weft directions.

Reactive Red 195 was purchased from Zhejiang Run Tu Co, Ltd. the dye information is shown in Table 1. Anhydrous sodium sulfate and anhydrous sodium carbonate were purchased from Sinopharm Group Chemical Reagent Co, Ltd., and A-502F soaping agent was purchased from Suzhou Lian sheng Chemical Company Limited.

Standard curve of Reactive red 195

Reactive red 195, 0.1 g, was added to deionized water and fixed volume to 100 mL used as dye mother solution with a concentration of 1 mg/L after stirring and dissolving. The dye mother solution was diluted to 0.0001, 0.0005, 0.001, 0.0015, 0.002 mg/mL respectively, and then the absorbance at the maximum absorption wavelength was measured to plot the standard curve of reactive red 195. Using the dye concentration as the abscissa and the absorbance at the maximum absorption wavelength as the ordinate (Tao et al., 2015), as shown in Fig. 3. The regression equation of the standard curve was fitted according to the dye concentration-absorbance value, and the fitting coefficient R2 was more than 0.999, which indicated that the fitting degree was good.